The Compressed Air & Gas Institute (CAGI) is a trade association of businesses actively engaged in the manufacture of compressed air equipment. Founded in 1915, CAGI consists of the leading manufacturers of air compressors, air drying and filtration equipment, blowers, nitrogen generators, and vacuum equipment.

The mission of CAGI is to be the united voice of the compressed air industry, serving as the unbiased authority on technical, educational, promotional, and other matters that affect the industry.

CAGI fulfills its mission through a number of objectives.

The Institute is governed by a Board of Directors, elected from member companies under a formula that ensures representation of both small and large companies.

Many of the activities of the Compressed Air and Gas Institute are carried out in its separate Sections, which are categorized by product scope. Individual member companies may affiliate with one or more of these Sections, depending upon their product lines.

Current Sections are Air Drying and Filtration, Blower & Vacuum, Centrifugal Compressor, Nitrogen Generation, Portable Air Compressor, Rotary Positive Compressor, Reciprocating Compressor, and System Assessment.

In addition, important work of the Institute is carried out by committees including the Education Committee, Promotion Committee, and Standards Committee.

The scope and responsibilities of these sections and committees are described in the committees and sections portion of this web site.

Important work of the Institute is carried out by standing committees that address topics of broad concern to the industry.

Education – The Education Committee is responsible for educating CAGI member employees, distributors, users, students, and the general public about compressed air equipment, compressed air systems, and the capabilities and benefits of compressed air. The Education Committee works closely with the individual Sections and CAGI Technical Consultant & Technical Editor, as required, to ensure all CAGI scope products are adequately represented in Institute material. The activities of the Education Committee include development and update of online training, maintaining the CAGI Handbook, and educational material posted on the website. The Education Committee coordinates its efforts with the Promotion Committee to ensure educational materials are promoted and appropriately distributed.

Promotion – The Promotion Committee is responsible for providing the industry and public with information about CAGI and the compressed air and gas industry. The material developed by the committee helps stimulate the markets for member-company products and compressed air systems by communicating the capabilities and benefits of compressed air. The activities of the Promotion Committee include the update and maintenance of website content, promoting educational materials, and collaboration with industry magazines and other organizations to promote compressed air. The Promotion Committee works with the Education Committee to help ensure that the educational material is promoted and appropriately distributed.

Standards – The Standards Committee monitors standards activity related to compressed air within the individual Sections of CAGI. CAGI maintains close liaison with other bodies concerned with standards, including ISO, Pneurop in Europe, ANSI, and other industry groups in the United States.

The Institute is structured by product section. Companies that manufacture products within the scope of CAGI and qualify for membership in the Institute can be a member of a section. Member companies may be affiliated with one or more of the sections, depending on their product lines. The sections include:

The Air Drying and Filtration Section consists of manufacturers of equipment used to treat air and gases that are compressed to pressures of 15 psig or higher. Dryers include desiccant, deliquescent, refrigeration, and membrane types. Filters used for the removal of liquids, vapors, aerosols, or solid particles include oil coalescing, particulate, and charcoal filters. Condensate management products include condensate drains and oil-water separation devices.

Section Members:

Altec AIR, LLC

Atlas Copco Compressors LLC

BEKO Technologies Corp.

Donaldson Company, Inc.

Hankison

Ingersoll Rand

Kaeser Compressors, Inc.

Lectrodryer

Mikropor America, Inc.

nano-purification solutions

Parker Hannifin Corporation, Industrial Gas Filtration & Generation Division

Pentair

Pneumatech

Quincy Compressor

Van Air Systems

Walker Filtration, Inc.

ZEKS Compressed Air Solutions

The scope of the Blower & Vacuum Section includes rotary positive displacement blowers/vacuum pumps and centrifugal blowers/exhausters in air or gas applications developing up to 28” Hg vacuum or up to 30 psig discharge pressure. Products include:

The scope of this section includes integrally geared, multi-stage centrifugal air compressors. Unlike positive displacement compressors, these compressors develop pressure by dynamic action. Centrifugal compressors are inherently oil-free and used in a wide range of industrial and process applications where large volumes of high-quality air are required.

The typical horsepower range for these products is 300 to 3000HP. While normally driven by an electric motor, these compressors can also be driven by other means such as diesel engines or steam turbines.

Section Members:

The Nitrogen Generation Section consists of manufacturers of equipment that generates onsite nitrogen from compressed air by utilizing either membrane technology or pressure swing adsorption (PSA) technology.

Section Members:

Atlas Copco Compressors LLC

BOGE America

Holtec Gas Systems

Mikropor America, Inc.

nano-purification solutions

Ozen Air Technology

Parker Hannifin Corporation, Industrial Gas Filtration & Generation Division

South-Tek Systems

The Portable Compressor Section consists of manufacturers of portable air compressors 30 cfm and above, usually defined as self-contained units designed for portability. A unit consists of a rotary positive air compressor, internal combustion engine, and internal accessory items necessary to cool and control its output as per ISO 1217 D1.1.A.

Section Members:

Kaeser Compressors, Inc.

Sullair – A Hitachi Global Air Power Brand

Sullivan-Palatek, Inc.

The Rotary Positive Compressor Section consists of manufacturers of rotary positive displacement compressors greater than 30 psig discharge pressure and vacuum pumps that develop vacuum over 28" Hg. Such compressors may be oil free, oil injected, or liquid injected. Rotary positive compressors include helical screw, sliding vane, rotary lobe, liquid ring, and scroll designs. This Section addresses both bare air ends as well as packaged units. Packaged units include both stationary installations as well as transportable, electric motor driven packages, which are distinct from internal combustion engine driven portable compressors.

Section Members:

Atlas Copco Compressors LLC

Aykom Compressor

BOGE America

Chicago Pneumatic Compressors

COAIRE, Inc.

Elgi Compressors USA, Inc.

FS-Curtis

Gardner Denver Inc

Hertz Kompressoren USA, Inc.

Hitachi America Limited

Ingersoll Rand

Jenny Products, Inc.

Kaeser Compressors, Inc.

Kaishan Compressor USA, LLC

Ozen Air Technology

Quincy Compressor

Sullair – A Hitachi Global Air Power Brand

Sullivan-Palatek, Inc.

Tamsan-USA

Compressor units within the scope of this Reciprocating Compressor Section are most frequently used for general purpose compressed air supply for applications in manufacturing, fabrication, assembly, automotive, construction, petroleum, natural gas, mining, painting, mobile service, shop service, farm service, home hobbyists as well as many others. Compressor units are typically tank or baseplate mounted and driven by an electric motor or an internal combustion engine. Products of this section also include all single & two stage basic compressor pumps.

Section Members:

Atlas Copco Compressors LLC

Chicago Pneumatic Compressors

FS-Curtis

Gardner Denver Inc

Ingersoll Rand

Jenny Products, Inc.

Quincy Compressor

Saylor-Beall Manufacturing Co.

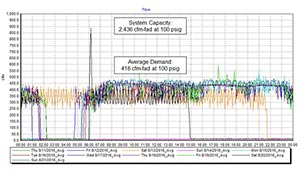

The principal focus of the System Assessment Section is developing and maintaining certification programs for compressed air system professionals and assessors.

Section Members:

Atlas Copco Compressors LLC

BOGE America

Gardner Denver Inc

Hankison

Ingersoll Rand

Kaeser Compressors, Inc.

Parker Hannifin Corporation, Industrial Gas Filtration & Generation Division

Quincy Compressor

Sullair – A Hitachi Global Air Power Brand

Tamsan-USA